Ionizers Testing and Repair Project

Github repository

Introduction

In our quest for continuous improvement and ensuring top-notch quality in the production of TVs, we embarked on a significant project to monitor and repair ionizers within our company's manufacturing plants. This project was born out of a comprehensive analysis that revealed a direct link between poor ionization and defects in our television products. To address this issue, we undertook the task of wiring all the ionizers in our production lines and implementing a robust monitoring system.

Project Overview

Our main objective was clear: monitor the ionizers in real-time to ensure their correct functioning and prevent any production line disruptions caused by subpar ionization. To achieve this, we used MOXA's Nport 5230 devices, connecting them to our Ethernet network and serially connecting each ionizer. Each ionizer had to be assigned a specific address to ensure seamless communication.

Testing the Ionizers

Before implementing the monitoring system, we needed to validate the ionizers' communication capabilities to control and monitor them effectively. For this purpose, we developed two versions of ionizer testers:

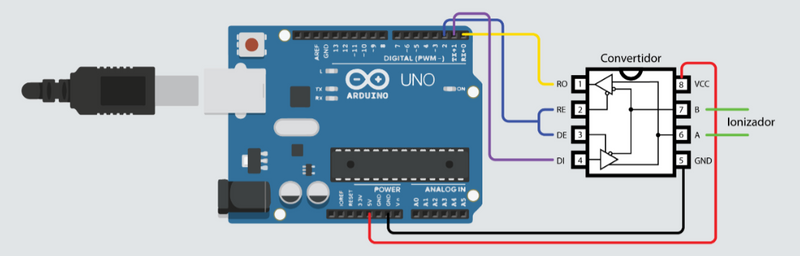

- Version 1 (Arduino-Based):

- Components: Arduino Uno, RS232 to RS485 module (required for the ionizers' protocol), 9-volt battery with an ON/OFF switch, and a fixed Ethernet connection to the ionizer.

- Challenges: Limited runtime due to high energy consumption, the need for manual cable replacement in case of damage, and difficulty in changing ionizer addresses.

Despite its limitations, we used this version successfully to detect defective ionizers, remove them from the production lines, and send them to our laboratory for assessment and repair.

- Version 2 (ESP8266-Based):

- Improvements: We addressed the shortcomings of the first version by using an ESP8266 microcontroller, allowing us to connect to the device's Wi-Fi server using our smartphones. This improvement not only reduced power consumption but also made it more convenient to send instructions to the tester via an RS232 app. Additionally, we switched to AAA batteries for power, which were readily available, and soldered a female RJ45 connector for easy communication cable replacement.

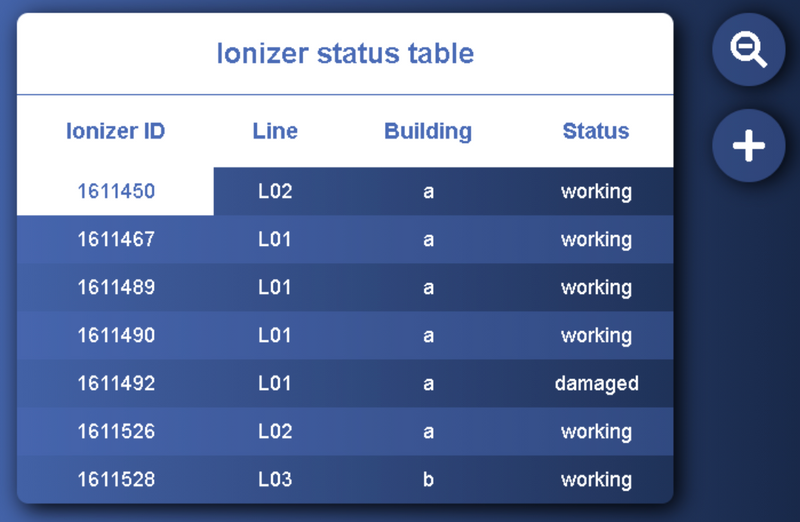

Tracking Ionizer Repairs and Installations

In parallel, we developed a dedicated webpage to keep track of repaired and installed ionizers in each plant and production line. This system allowed us to maintain a comprehensive record of ionizer status, enabling quick responses to issues and efficient planning for future installations.

Conclusion

The Ionizer Monitoring and Repair Project has been a significant step toward enhancing the quality and efficiency of our TV production process. By implementing this monitoring system and developing improved ionizer testers, we have not only identified and rectified ionizer defects promptly but also ensured a smoother production workflow.

We continue to explore innovative solutions to optimize our manufacturing processes, and this project is just one example of our commitment to excellence. Stay tuned for more updates on our journey toward excellence in television production.